Research

In our research group, we focus on the characterization of various solid fuels using a wide array of experimental techniques and numerical tools. The solid fuels studied are endogenous lignite coal currently fired in thermal power plants in Turkey, and biomass fuels of agricultural origin that present potential for large-scale utilization.

The topics that we focus on include, but are not limited to,

• Biomass torrefaction / pyrolysis / gasification

• (Co-)combustion of coal with biomass

• (Co-)gasification of coal with biomass

• Combustion kinetics

• Pollutant formation

• Ash formation and applications

• Bioplastics classification / pyrolysis / combustion

Projects at CCTL

• Investigation of Combustion Behaviors of Reactive Metallic Nano coats (BAP ODTÜ, 2020-2021)

• GeoSmart (European Union's Horizon 2020 Research and Innovation Programme - Grant Agreement 818576, 2019-Ongoing)

• Investigation of Zeolite 4A and 13X Synthesis Potential of Fly Ashes Obtained by Burning Tunçbilek and Seyitömer Lignite with Different Combustion Parameters (TUBITAK 1001, 2019-Ongoing)

• Development of Solar Drying Technologies for the Valorization of Sludge (Tunisia Project, 2018-Ongoing)

• Flexible Oxy-Combustion for Turkish Fuels (Royal Society UK, Advanced Newton Fellowship, 2015-2018)

• An Observation on Pulverized Combustion Behavior of Co-Firing Turkish Lignite with Various Biomasses and Waste Magnesite Dust in a Drop Tube Furnace (TUBITAK, Career Project, 2015-2018)

• The Effects of Co-Firing Turkish Lignite with Various Biomasses and Waste Magnesite Dust On combustion Characteristics (BAP ODTÜ, 2015-2016)

• Experimental and Theoretical Investigation of Afşin - Elbistan Lignite Combustion Behaviour in Drop Tube Furnace (BAP ODTÜ, 2018-2019)

• Zeolite Synthesis from Fly Ash: Synthesis and Characterization (BAP ODTÜ)

Facilities at CCTL

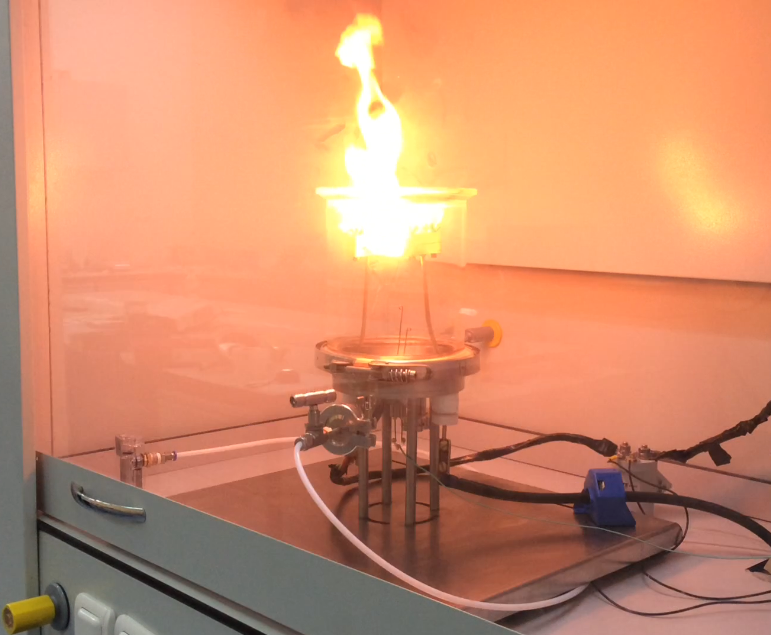

Wire Mesh Reactor (WMR)

The WMR is a flexible, user-friendly, and optically accessible setup. In this WMR, pyrolysis, and combustion of solid fuels at high temperatures (1000-1500 °C) and at high heating rates (1000 ºC/s) is typically performed. This WMR is fitted with a high-speed camera to record combustion events that take place in the microsecond scale. The solid post product is oftentimes collected for subsequent analysis using tools such as X-Ray Fluorescence, X-Ray Diffraction, or Scanning Electron Microscopy.

Wire Mesh Reactor (WMR) Combustion @ ~1040 °C Pyrolysis @ ~1100 °C

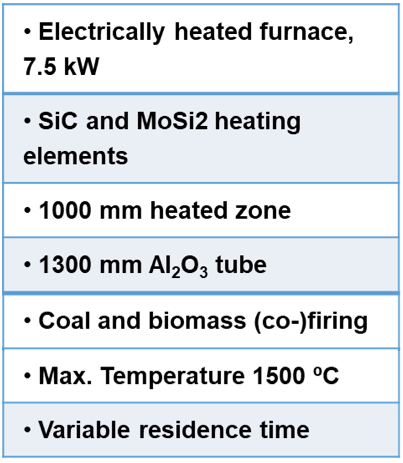

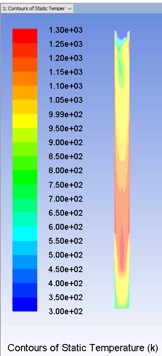

Drop Tube Furnace (DTF)

Drop tube furnace is an electrically heated furnace that allows high heating rate and high-temperature conditions and maintains variable gas compositions. The setup consists of a drop tube furnace, a feeding system, and a collection unit. This type of furnaces is typically used for pyrolysis, combustion, and gasification studies. Data that can be collected consists of solid particles and gaseous combustion products. Studies focus on combustion kinetics, particulate matter formation, and greenhouse gas emissions.

Drop Tube Furnace (DTF) DTF Feeding Unit DTF Parameters Temperature Contour

Muffle Furnace

A muffle furnace is a widely used laboratory furnace that can be used for different purposes. In our laboratory, it is mainly used to determine the moisture and ash contents of the fuel under analysis. This furnace operates at low heating rates and can reach 1100 ºC. Its operation following ASTM standard procedures is recommended.

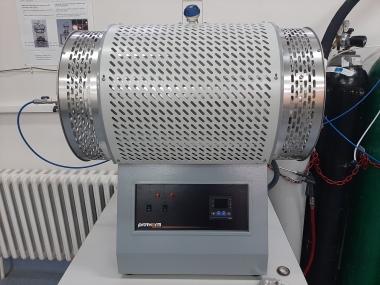

Horizontal Tubular Furnace

This horizontal furnace is used to perform tasks that require high temperature and/or well-defined gas composition. Low temperature (300ºC) and inert atmosphere applications include torrefaction of biomass. High temperature (up to 1300 ºC) applications can include fast-pyrolysis and combustion. Since high temperatures can be reached, slagging and fouling during the combustion of coal and/or biomass can also be studied using deposition probes.